Current information about explosion protecton for equipment and machines

With our current technical information, we want to keep you up to date – compact and clear. Benefit from the know-how gained from decades of experience in different application areas of explosion protection.

Dust explosion protection for equipment and machines (2)

February 2024

Equipment and machines for hazardous areas - Avoid potential ignition hazards

Ignition sources for combustible dusts can be caused by both electrical and non-electrical equipment.

The maximum temperature of surfaces on which dust may be accumulated or which may come into contact with dust cloud must be kept below the defined temperature limit. For the max. permissible surface temperature of the equipment , the smallest value calculated from the minimum ignition temperature of the dust layer (T5 mm: Tmax. < T5 mm – 75 °C) and the minimum ignition temperature of the dust cloud (TCL: Tmax. < 2/3 TCL) is used.

In addition to the ignition temperature, the conductivity of the dust is a key parameter and a selection criterion for appliances. Equipment group IIIC applies for use with conductive dusts and equipment group IIIB for non-conductive dusts.

With the principle of dust-tightness or protection by enclosure (Ex t, IEC 60079-31), any sparks are enclosed by an enclosure. The ingression of a surrounding dust atmosphere into the enclosure is permanently prevented by a high degree of dust protection (e.g. IP 6X for conductive dusts). This principle can be used for both electrical and non-electrical equipment and machines and is suitable for all levels of equipment protection.

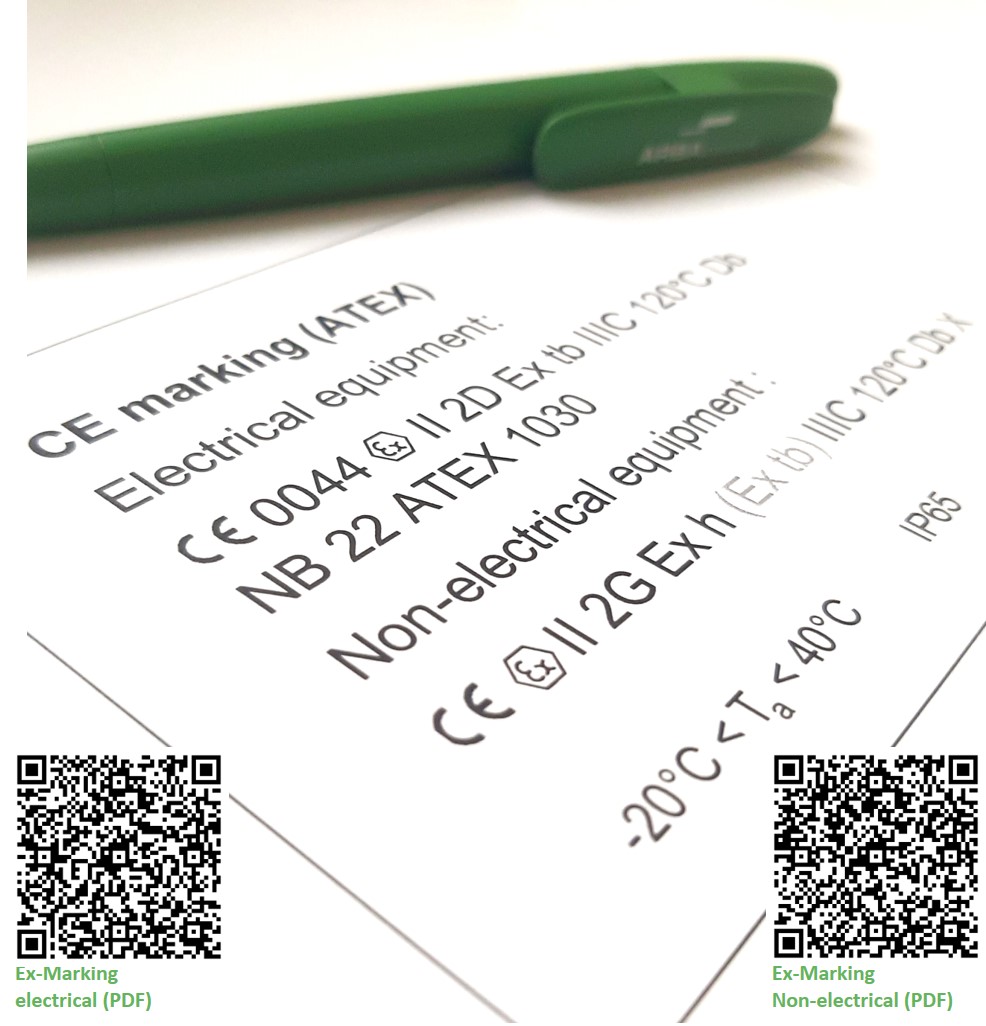

The ignition protection measures and the suitability of the equipment or machine in the DustEx area can be recognised by the comprehensive marking on the nameplate.

Any questions? We will answer

Register now for ContExt information.

Dust explosion protection for equipment and machines (1)

January 2024

Description of the safety-related DustEx parameters

In industrial facilities with combustible dusts, there is always a risk of explosion. The requirement for this is a certain concentration of dust in the air in conjunction with a potential ignition source. The primary focus should therefore remain on measures that reduce the amount or concentration of dust in a workplace (cleaning, extraction).

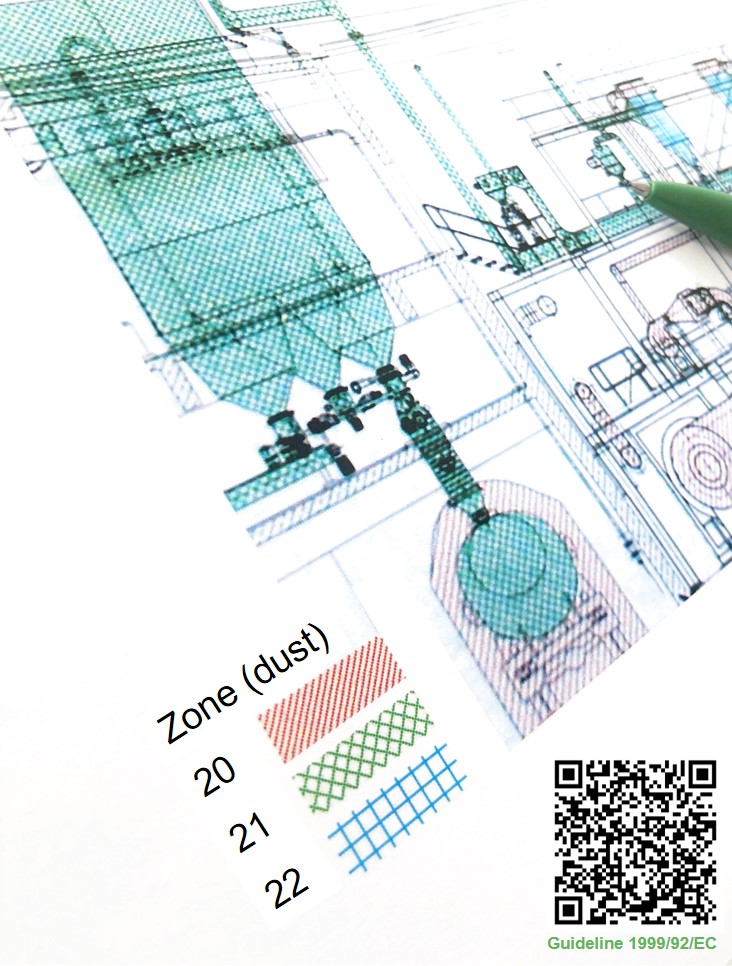

Companies are responsible for analysing and minimising the risk of dust explosions (Directive 1999/92/EG). This includes a detailed analysis of the safety-related dust characteristics and a comprehensive classification of the working environment into zones.

Dusts behave differently to gases and vapours

| Characteristics of the flammable substances | Gases, Vapours (G) | Dusts (D) | ||

|---|---|---|---|---|

| Miscibility with air and demixing | Good, permanent No, difficult | Due to air flow, limited in time Sedimentation due to gravity | ||

| Density difference to air and particle size | Relatively low, Molecule (e. g. CH4) | Large, Dependent on technical condition | ||

The safety definition for dusts is usually more complex than for gases and vapours. As a general rule, the finer the dust, the higher the risk.

Knowledge of the essential safety-related dust explosion protection parameters and the ambient conditions (e.g. temperature) is crucial for the necessary level of protection and therefore the selection of suitable Ex equipment. Depending on the temporary behaviour of the explosive dust atmosphere (cloud), Ex areas are categorised into zones:

| Conditions and zones | Requirements for equipment | ||||

|---|---|---|---|---|---|

| The explosive dust atmosphere (cloud) is ... | Classification Ex-areas | Group (Directive 2014/34/EU) | Equipment category (Directive 2014/34/EU) | Equipment group (IEC 60079-0 ff. & ISO 80079-36) | Equipment protection level (EPL) IEC 60079-0 ff. & ISO 80079-36) |

| Constant, long-term or frequent presence | Zone 20 | II | 1 D | III | Da |

| in normal operation occasionally | Zone 21 | II | 2 D or 1 D | III | Db or Da |

| in normal operation normally not or only for a short time | Zone 22 | II | 3 D or 2 D or 1 D | III | Dc or Db or Da |

Any questions? We will answer

Register now for ContExt information.

Product or simple product according to ATEX?

October 2023

In order to answer this question in a specific case, it is worth taking a look at the guideline of Directive 2014/34/EU. The analysis of the “own potential ignition sources” is crucial for the classification.

Products for use in hazardous areas

Electrical equipment always and mechanical equipment very often have their own potential ignition source, e. g. hot surface. Potential means that the energy of the ignition source is sufficient to ignite an explosive atmosphere. In accordance with Directive 2014/34/EU, Ex equipment (products) require the CE marking and proof of conformity depending on the category, the protective measures as well as the testing and certification. The manufacturer must ensure this. The focus is on safe use in hazardous areas.

“Simple products” for use in hazardous areas

With hand-operated devices (pumps, valves) that are operated with human power, the slow movement does not create such a hot surface. Therefore, these simple products do not fall within the scope of Directive 2014/34/EU. The manufacturer must still check his device with regard to “own potential ignition sources” and decide whether the ATEX directive applies. The simple products can be used in areas with explosive atmospheres without any category, special protection and compliance measures. However, for safe use, the user must consider and avoid the remaining ignition hazards, e. g. from an electrostatic ignition source.

Any questions? We will answer

Register now for ContExt information.

Helpful know-how sources for assemblies

April 2023

In most cases, pumps, centrifuges, compressors and mills are placed on the market and put into operation as a group of equipment, i.e. as a functional assembly. Both the guidelines for the ATEX Directive 2014/34/EU and IEC TS 60079-46 define these prefabricated combinations as an assembly of electrical or mechanical Ex equipment to form a functional unit.

For the planning and configuration of such equipment device combinations, IEC TS 60079-46 provides helpful approaches for evaluation, design, assembly, marking and documentation. The requirements from the certificates and terms of use of the individual Ex equipment must be brought in to line.

The group's overall documentation also includes wiring systems, drawings, material specifications, system interfaces and verification of intrinsi safety (Ex i), ignition hazard assessments, calculations, plans for inspection. In addition to the general requirements for electrical installations, the Ex specifics from IEC 60079-14 also apply.

In order to obtain a systematic and inexpensive overview of the lowest common denominator for the conformity statement of an assembly, the preparation of a detailed equipment list with all important Ex parameters and special conditions of use is essential. IEC TS 60079-46 recommends preparing such an Ex equipment list with the specifications for explosion protection or the Ex equipment marking (e.g. equipment protection levels, product category, types of protection, temperature class, Ex subgroup, ambient temperature range, IP protection type and special conditions for safe use). This also makes it easier to combine the special user conditions and communicate them to the user.

In complex machines, pre-certified electrical and non-electrical individual components are very often combined to form new equipment groups. In the future, the Ex marking of the individual equipment will be available more and more digitally via standardized information structures and communication technologies (Industry 4.0). This structured product data (administration shell in the meaning of Industrie 4.0) also represents a practical interface for data exchange. The preparation of an Ex equipment list, which is also used to determine the most critical Ex parameter of the Ex marking of the equipment group, can be greatly simplified with the help of a digital Product ID Card and the corresponding product data.

Any questions? We will answer

Register now for ContExt information.

Ex-products for market entry in the United Kingdom

December 2022

The UK government announced on 14th of November 2022 that companies will be given two more years to affix a UKCA marking to Ex products.

While can already use UK Conformity Assessed (UKCA) marking on their products, the UK government has stated that CE marking will continue to be recognized until 31st December 2024.

August 2022

With the execution of Brexit on 31st of December 2020 the United Kingdom (UK) has left the EU Internal Market. Since then, UK-specific product rules of conformity have applied to market entry. After some postponements, from 01st of January 2023 only Ex equipment will be accepted that have a UK Type examination certificate from a UK approved body (UKEX Approved Body, British equivalent of an ATEX notified body). ATEX certificates (EU) are no longer accepted in the UK. Ex equipment must have a UKCA marking (mandatory), CE marking is no longer acknowledged. For future product developments for the EU market and for the UK, the manufacturer should consider that the evidence of conformity must be kept separately for each guideline (EU/UK).

Comparison of the systems

The UKEX system is structured similarly to the ATEX system. The technical requirements of the UKEX system are nearly identical to those of the ATEX directive. The longstanding exchange between the certification bodies and surveillance authority in Europe in the sector of explosion protection has certainly also contributed to this. The knowledge gained by experts in the EU and UK is now also used in the practical implementation of the UKEX system. In both directives, the conformity process and thus the assignment of an authorized certification body or manufacturer's declaration is dependent on the required product category (1, 2 or 3). The following overview with the essential differences and similarities should help with the implementation.

| CE/ATEX (valid in EU) | UKCA/UKEX (valid in UK) | |||

|---|---|---|---|---|

| Directive | ATEX - Directive 2014/34/EU | SI 2016 No. 1107 (amended in SI 2019 No. 696) | ||

| Standard basis | Harmonized standards (EN) | Designated Standards (EN, BSI) | ||

| Certification bodies | Notified Body | Approved Body | ||

| Conformity process | by equipment assembly and category | by equipment assembly and category | ||

| Third party certification (Certification bodies) | EU Type examination certificate Group II, Cat. 1,2 electrical Group II, Cat. 1 non-electrical | UK Type examination certificate Group II, Cat. 1,2 electrical Group II, Cat. 1 other (non-electrical) | ||

| Self-declaration (manufacturer) | Group II, Cat. 3 electrical Group II, Cat. 2,3 non-electrical | Group II, Cat. 3 electrical Group II, Cat. 2,3 other (non-electrical) | ||

| Quality Assessment Report | QAN | UK QAN | ||

| Manufacturer's declaration | EU Declaration of Conformity | Declaration of Conformity | ||

| Marking | CE Marking (Ex mark) | UKCA Marking | ||

Transcription of existing certificates

The requirements of the UKCA conformity process (SI 2016 No. 1107 amended to SI 2019 No. 696) must be implemented by the manufacturer. Certification bodies holding EU and UK accreditations will be able to support the transcription of ATEX equipment. Ex-assessments (ATEX) and EU Type examination certificates can be used as a basis to issue corresponding UKEX certificates (UK Type examination certificates) for the British market. In the case of equipment combinations or integrated components from third-party suppliers, all parts must have a UK Type examination certificate from a British approved body.

Direct and useful links

Designated standards: equipment for explosive atmospheres

Any questions? We will answer

Register now for ContExt information.

Overall assessment of the ex-machine

February 2022

Explosion protection is a comprehensive task that requires special know-how in all project phases: from sales and engineering to purchasing and production. It is important to consider the product as a whole.

Manufacturers of machines and assemblies are responsible for the function, the economic success of a project, but above all for the safety of the complete Ex machine. For equipment and machines for use in potentially explosive atmospheres, harmonized safety requirements have been applied in the EU with the ATEX Directive 2014/34/EU and EN standards. Outside Europe, explosion protection regulations are based primarily on IEC/ISO standards and corresponding IECEx certificates or national regulations or certificates.

The two ContExt brochures (only available in German) summarize the most important information on ATEX/IECEx marking of electrical and non-electrical explosion-proof equipment. They form a unit and serve as a compact guide for manufacturers of machinery:

Any questions? We will answer

Register now for ContExt information.

Equipment and Installations in Ex-areas

November 2021

In terms of explosion protection (ATEX, IECEx), machines are regarded as equipment or as a combination of different equipment (Equipment Assemblies). The interconnection/installation of electrical Ex-equipment (sensors, controllers, actuators, motors), on the contrary, is seen as an installation.

The following overview shows definitions and correlations to the terms from the ATEX Directive and the relevant standards.

Valuable information on the implementation of the ATEX Directive 2014/34/EU can be found in its Guidelines.

| ATEX (only EU) | Standards (DIN, EN, IEC) | |||

|---|---|---|---|---|

| Equipment | As defined in the ATEX Directive as well as in the standards, Equipment means machines, apparatus, fixed or mobile devices, control components and instrumentation thereof and detection or prevention systems which, separately or jointly, are intended for the generation, transfer, storage, measurement, control and conversion of energy and/or the processing of material and which are capable of causing an explosion through their own potential sources of ignition. | |||

| Falls within the scope of application of the ATEX Directive 2014/34/EU. The ATEX Directive 2014/34/EU defines equipment categories(1G, 2G, 3G or 1D, 2D, 3D) for use in the zone (0, 1, 2 or 20, 21, 22). | DIN EN IEC 60079-0 defines electrical equipment that is used to apply electrical energy. DIN EN ISO 80079-36 defines non-electrical equipment with mechanical function. The DIN EN IEC or ISO standards define levels of protection (Ga, Gb, Gc or Da, Db, Dc) for use in the zone (0, 1, 2 or 20, 21, 22). According to DIN EN IEC 60079-14, a distinction is also made: Fixed equipment: Equipment that is attached to a fixture or otherwise secured in a fixed location when energized. Transportable equipment: Equipment that is not intended to be carried by a person, but is also not intended to be permanently installed and can be moved while energized. Portable equipment: Equipment intended to be carried by one person and which can be moved while energized. Personal equipment: Equiment intended to be worn on a person's body when used as directed. | |||

| Installation | Installation is an entity which is made from parts previously considered separately but which are only put together at the point of application. Installing such equipment at the end-user premises or under his responsibility will generally be subject to legal requirements either from the workplace directives or the domestic legislation of the Member States. It does not fall within the scope of application of the ATEX Directive 2014/34/EU. It is defined in the Guidelines to the ATEX Directive 2014/34/EU. | The DIN EN IEC 60079-14 standard does not provide a definition for an "installation" as an entity, but is a technical guide for the installer. It defines that an installed system complies with the equipment documents (certificates and instructions for safe installation) as well as the installation requirements (DIN EN IEC 60079-14) and all other requirements (rele-vant to the system). Verification documents must be prepared for the overall result and kept in an accessible place. | ||

Any questions? We will answer

Register now for ContExt information.

ATEX and IECEx certification: a useful combination for mechanical engineering

August 2021

The consequent standardization of technology in the field of explosion protection for electrical equipment, which began over 100 years ago, is now based on mature IEC standard (EN IEC 60079-0 ff). The introduction of international ISO standards (EN ISO 80079-36, -37) for explosion protection of non-electrical equipment supplements the electrical standards. The visible identification for non-electrical equipment is the protection type Ex h and the equipment protection level (EPL). The proven principle of graduation of explosion protection measures with equipment protection levels for use in Ex zones is now also applied to non-electrical equipment.

Basically, a holistic view of the machine or system according to state-of-the-art technology (standards) is required both within and outside of Europe. The important task for the manufacturer of machines is the risk assessment of ignition sources, construction, the definition of ignition protection measures, testing, certification, and the conformity assessment. According to both ATEX and IECEx, inspection bodies must be involved.

ATEX is a legal system (Directive 2014/34/EU) of the EU and regulates the market access for products to be used in Ex areas. IEC is an international standardization organization also for equipment to be used in Ex areas. The IECEx system serves for certification of conformity with the IEC standards and is voluntary in Europe.

The following table provides a comparison of the two systems and contains further links.

Comparison of the ATEX- and IECEx-Certification

| ATEX | IECEx | ||

|---|---|---|---|

| Validity | Required by law in the EU | Voluntary in the EU Different acceptance worldwide | |

| Directives and standards | RL 2014/34/EU EN IEC 60079-0 ff EN ISO 80079-36 and -37 | IEC 60079-0 ff ISO 80079-36 and -37 | |

| Conformity for electrical equipment | Cat. 1 und 2: Quality Assessment Report EU Type examination certificate EU Declaration of conformity CE Marking | Cat. 3: Internal production control EU Declaration of conformity CE Marking | EPL a, b, c: Quality Assessment Report (QAR) Test Report (ExTR) Certificate of Conformity (CoC) Marking |

| Conformity for non-electrical equipment | Cat. 1: Quality Assessment Report EU Type examination certificate EU Declaration of conformity CE Marking | Cat. 2* und 3: Intrernal production control EU Declaration of conformity CE Marking *Technical documentation at notified body (deposit) | EPL a, b, c: Quality Assessment Report (QAR) Test Report (ExTR) Certificate of Conformity (CoC) Marking Used similar to electrical equipment (for all EPLs the same) |

| Access to certificates | EU type examination certificate (manufacturer, online) EU declaration of conformity (manufacturer) | IEC Online Database with IEC CoCs | |

Any questions? We will answer

Register now for ContExt information.

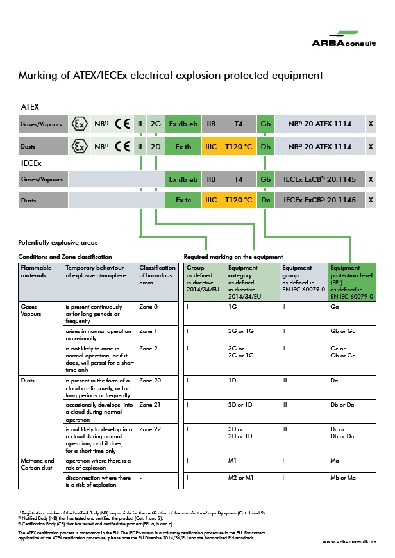

Engineering and installation of electrical Ex-equipment

June 2021

Standardized electrical equipment is often individually planned and installed on the basis of specific customer requirements. While engineering the Ex-solution, it is crucial to carefully examine all relevant Ex aspects at an early stage.

The specifications in the context of explosion protection must be carefully coordinated with the customer, i. e. the Ex-parameters, e. g. zone classification/equipment categories as well as Ex parameters for flammable substances (gases, vapors and dusts). Based on this the suitable suppliers for electrical equipment are selected.

The engineering, installation and initial testing of the electrical Ex equipment and systems should be implemented professionally. For this mix of tasks, planners and electricians can find comprehensive information in DIN EN IEC 60079-14 for the selection and installation of electrical devices in Ex areas.

For electrical Ex devices, their marking provides all the essential information. (PDF)

Electrical equipment for switching, controlling, regulating, mobile or stationary, naturally find their way into safe Ex-applications today. The development of internationally uniform protection concepts and standards (EN IEC 60079-0 ff) in electrical engineering have made a decisive contribution to this. If necessary, Ex technologies (types of protection) must be implemented internally using the relevant standards.

Any questions? We will answer

Register now for ContExt information.

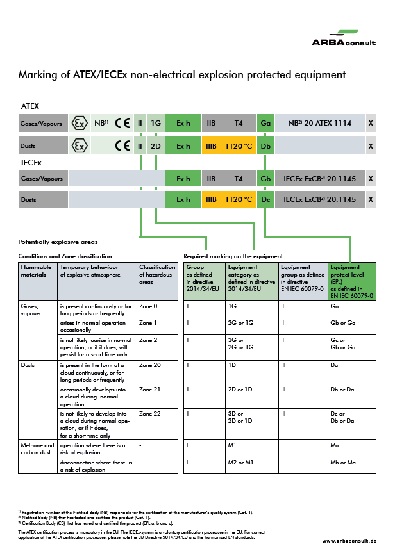

Construction and certification of mechanical Ex-equipment

April 2021

Non-electrical equipment is often implemented individually on the basis of specific customer requirements. The specification in the context of explosion protection (zones/equipment categories, Ex parameters: temperature class,

Ex group) is decisive for the construction of the Ex-machines. This must be coordinated with the customer carefully and at an early stage.

In the EU, the ATEX Directive 2014/34/EU has always provided a legal basis for the testing and certification of mechanical equipment and assemblies for use in Ex areas. The IECEx system has been offering a similar certification framework for mechanical equipment and combinations outside the EU for about 2 years.

The systematic ignition source assessment is the starting point for the definition and implementation of individual ignition protection measures and the application of suitable types of protection (Ex h). The international standards for non-electrical Ex devices (EN ISO 80079-36, -37) provide the technical basis and support for this. They complement the IEC standards and thus expand the Ex-requirements for process machines.

The new Ex marking for non-electrical devices (PDF) with the Ex h type of protection and the device protection values Ga, Gb, Gc (gases) or Da, Db, Dc (dust) gives information for safe use in Ex zones and are a clear identifier for the implementation of the new standards.

Any questions? We will answer!

Register now for ContExt information.

The ARBAconsult

We offer knowledgeable Consulting, Trainings and Workshops in explosion protection. Benefit from our know-how out of decades of experience in different industries and niches

Ask our contact person

Johannes Buhn

Executive Director

Technology, Product and Market Development

johannes.buhn@arbaconsult.de

Phone: +49 931 46558-16

vCard